Have you ever wondered how those shiny, durable coatings are applied to floors and countertops? Chances are, they were made with epoxy resin.

Epoxy is a versatile adhesive used for various applications, including sealing, bonding, and coating surfaces. However, mixing and applying without experience or knowledge can be tricky.

This article will guide how to mix epoxy resin and hardener, from understanding the types of epoxy available to troubleshooting common problems. Following these steps and safety precautions, you can confidently mix and apply epoxy for your next project.

So let’s dive in!

Key Takeaways

- Surface preparation is crucial for good adhesion and durability.

- Precise measuring and thorough mixing of epoxy for 2-3 minutes is necessary.

- Optimal epoxy resin mixing ratio chart and technical data sheets provide essential information.

- Post-application care, such as adequately cleaning tools and storing leftover epoxy, can impact the curing process and durability.

Types of Epoxy

Understanding the different types of epoxy resins available can aid in selecting the appropriate mixture for a given application, as each type offers unique properties and characteristics.

Types overview includes:

- Allyl glycidyl ether epoxies.

- Bisphenol A Diglycidyl Ether (DGEBA).

- Aliphatic epoxy resins.

- Novolac epoxy resins.

- Brominated bisphenol A.

Each type has distinct advantages: toughness, chemical resistance, strong adhesion, weather resistance, low dielectric constants, high Tg, flame resistance, or no VOCs.

Application techniques may vary depending on the surface being used; however, proper surface preparation is essential to ensure good adhesion and durability of the epoxy coating.

The epoxy curing process involves a reaction with itself or forming a copolymer featuring polyfunctional hardeners or curatives.

Depending on user preference, color options are also available for specific applications, from clear to opaque colors.

Safety Precautions Before Mixing Epoxy

Before commencing the epoxy mixing process, it is essential to adhere to a range of safety precautions to minimize potential hazards associated with handling this material.

This entails the use of protective gear, such as gloves and eye protection, to prevent skin contact or inhalation of vapors.

Respiratory protection like dust masks and respirators should also be used in unventilated workspaces.

Proper ventilation systems must be installed in small workshops or confined spaces to avoid inhaling fumes and sanding dust.

Additionally, unused epoxy should be disposed of properly by puncturing the can and draining any residue into a new container for disposal, as disposal of resins or hardeners as liquids can have negative environmental impacts.

Adhering to these safety measures is crucial in minimizing accidents when working with epoxy resin materials.

Related Post

You can check Is epoxy resin flammable from our team

You can also check Epoxy vs Resin

Materials and Tools Needed for Epoxy Project

To properly prepare for an epoxy resin project, it is essential to have the appropriate tools and materials readily available. These include:

- Mixing cups with labeled ounces and liters for accurate pouring measurements

- Mixing sticks for tabletop epoxy

- A drill for deep pour epoxy

- Wooden skewers for adding details and swirls to epoxy

- Upstart Epoxy Powdered Pigments Set for adding color and depth

- A mold that doesn’t stick and has good reviews

- An orbital sander from 60-grit to 220-grit sandpaper for a clean surface finish

It is also important to have flood and seal coats with tabletop epoxy for finishing projects, as well as a heat gun or torch to pop any surface bubbles.

Furthermore, prior knowledge about the proper mixing techniques is necessary to ensure the best outcome of the curing process. After mixing epoxy resin thoroughly with its hardener in the correct ratio, it’s essential to let it rest before using it on your project.

Surface preparation should also be done before applying the mixed resin on any surface, such as cleaning it thoroughly and removing all dust particles present.

Post-mixing handling should be done carefully because exposure can lead to skin irritation or respiratory problems; thus, wearing gloves, masks, and safety goggles is recommended throughout this process.

Finally, any remaining material should be kept in a dry place at room temperature and, if feasible, shielded from direct sunlight until it can be disposed of in an environmentally safe way and compliant with local regulations.

Read more: Is epoxy conductive

Measuring and How to Mix Epoxy

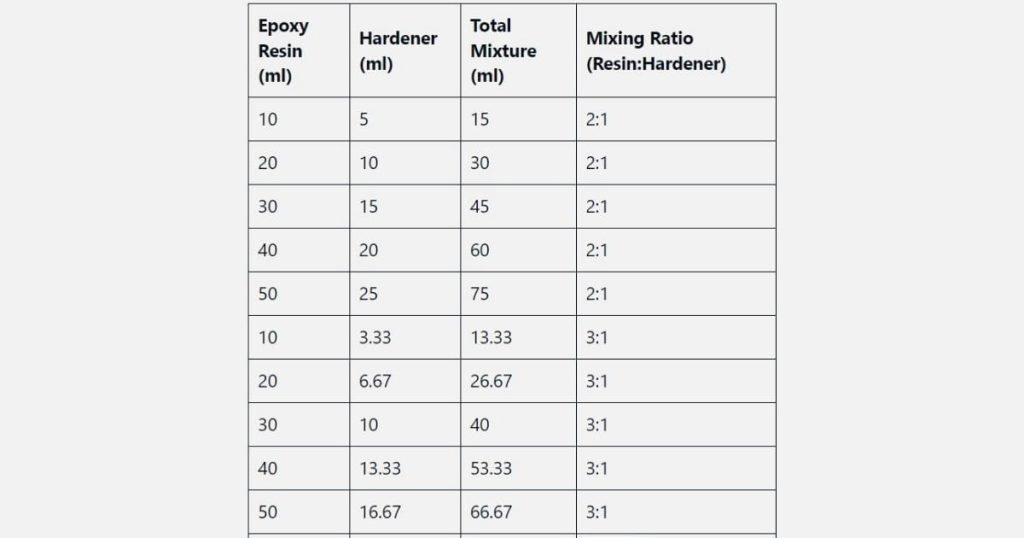

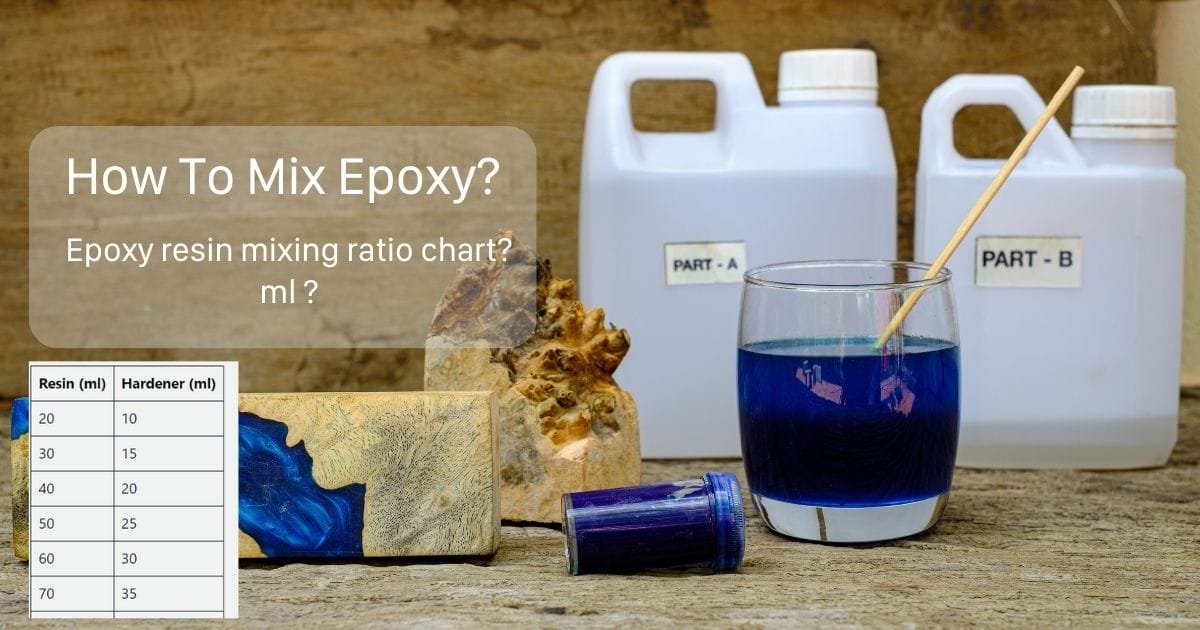

Mastering the art of proper epoxy resin mixing involves precise measuring and meticulous attention to detail. One crucial aspect is following the right ratios, which for Entropy Resins’ Super SAP CLR epoxy resin system is 100:47 by weight or 2:1 by volume.

| Epoxy Resin | Hardener | Application |

| 1 part | 1 part | General purpose, ideal for most projects like coating, casting, and art projects. |

| 2 parts | 1 part | More flexible and better suited for applications where flexibility is needed, like some adhesive applications. |

| 3 parts | 1 part | Typically used for specialized applications, like high-temperature environments or industrial uses. |

Remember, these are general guidelines and may not apply to every epoxy resin product on the market. Always consult the manufacturer’s instructions for the specific mixing ratio and curing times for the epoxy resin you are working with.

Measuring by weight or volume using digital scales or graduated cylinders is necessary, as well as using clean equipment such as gloves, cups, and mixing sticks. Thorough mixing for 2-3 minutes and scraping the sides, corners, and bottom of the container are essential techniques to ensure a homogenous mixture.

Viscosity control is also essential when preparing epoxy resin, as it affects the ease of application and final appearance of the project. To manage viscosity, it is necessary to consider temperature considerations during mixing. Epoxy should not be applied in cold temperatures or high humidity conditions, as this may affect curing time and cause bubbles in the resin. Other factors that can impact viscosity include color additives and application techniques.

Dispensing the resin in a controlled manner and avoiding variations in temperature and humidity can also affect curing time. Additionally, color additives can be mixed into the epoxy resin before application to achieve desired effects.

The Working Time and Pot Life of Epoxy Resins

Understanding epoxy adhesives’ working time and pot life is essential for achieving optimal results when using mixed epoxy.

The pot life is the time for the initially mixed viscosity to double, essential for multiple-part coatings or paints. It usually takes 25 minutes if the initial density of 10,000 cps increases to 20,000 cps after 25 minutes but quadrupled for lower viscosity products (1000 cps).

The working life refers to the time and temperature needed to work with the material before it becomes too dense, which is defined by the resin supplier as essential for producing a good part.

Dry time, also called recoat time, is another crucial factor determining the quality of finished projects, while cure time indicates how long it should be left before daily use.

Optimal ratios and strength information are specified in technical data sheets, while color options may vary depending on product type.

Post-application care, such as cleaning tools and storing leftover epoxy properly, can also impact its curing process and durability.

Troubleshooting Common Epoxy Mixing Problems

To ensure the successful use of mixed epoxy, it is crucial to understand and troubleshoot common mixing problems.

Air bubbles can be prevented by gently stirring the mixture rather than vigorously mixing it, while uneven color can be avoided by thoroughly blending the resin and hardener.

Hardening too fast could be due to incorrect mixing ratios or high temperatures, so carefully following instructions and keeping an excellent workspace can help prevent this issue.

Uncured spots may occur if the mixture is not blended well enough or applied on a surface that is too cold, so proper preparation and application techniques should be utilized.

Overall, understanding these common issues and taking preventative measures can result in the more successful use of mixed epoxy.

Conclusion

Epoxy is a versatile adhesive used for various bonding, coating, and filling applications. Choosing the correct type of epoxy and learning how to mix epoxy is crucial to ensure successful results. Before commencing any mixing process, it is essential to prioritize safety and gather the necessary materials and tools.

Precise measuring and thorough mixing are vital for a strong bond or durable coating. Understanding mixed epoxy’s working time and pot life can help prevent any potential issues.

In conclusion, mastering the art of mixing epoxy requires patience, attention to detail, and practice. As with many things in life, it may take some trial and error before achieving optimal results.

Remember that Rome wasn’t built in a day; therefore, do not be discouraged by common problems encountered when working with epoxy – they can always be resolved!

You have mentioned very interesting points! ps decent internet site.Blog range