Have you noticed dents on your cups tumbler and wondered why does my epoxy tumbler have dimples? As an epoxy coke researcher, I’ve often encountered this question.

Convexity can be an undesirable attribute that affects the overall aesthetic of the Tumbler, leading to the frustration of individuals who have put in the time and effort to create a seamless design.

Several factors can contribute to dents on the epoxy cup. One of the leading causes is improper mixing of epoxy resin and curing agent.

These can lead to air bubbles getting trapped in the mixture, creating uneven surfaces and dents after being cured.

Other factors, such as temperature changes during curing, using too much or too little heat, or using low-quality epoxy resin, can also lead to dents.

In this article, we will explore why epoxy cups can have dents and how to prevent them from happening. So if you want to improve your epoxy cup game, keep reading!

Common Causes: Why Does My Epoxy Tumbler Have Dimples?

I’m researching common causes of dimples and bumps in epoxy tumblers.

Incomplete mixing can lead to surface unevenness, so thorough epoxy mixing is essential. Trapped air bubbles can also create bumps and dimples, so it’s important to agitate the epoxy often during curing.

Temperature fluctuations can also cause warping and cracking, so it’s crucial to maintain a consistent temperature during the curing process.

Proper mixing, agitation, and temperature regulation are essential to avoid dimples and bumps in epoxy tumblers.

Incomplete Mixing

Hey there! As an epoxy tumbler researcher, I’ve encountered many causes of dimples and bumps in epoxy tumblers.

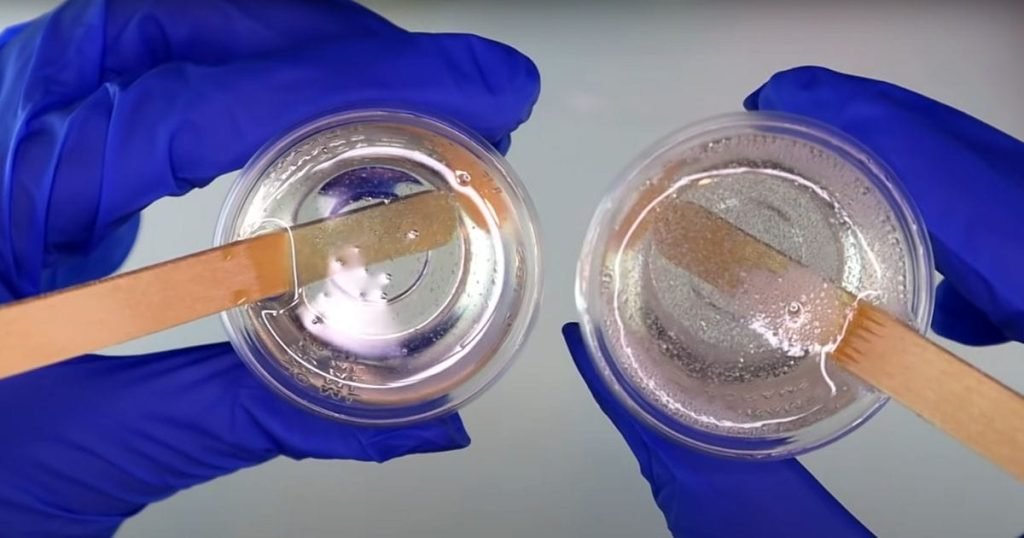

One of the most common reasons is incomplete mixing of the epoxy resin and hardener, which can lead to uneven curing and air pockets forming. Properly mixing your epoxy is essential to avoid this issue, ensuring you accurately measure and mix thoroughly for at least 3-5 minutes.

Additionally, temperature control during the curing process can also play a role in creating dimples or bumps. Following the recommended curing time and maintaining consistent temperatures throughout the process is crucial.

Finally, checking for proper epoxy consistency before the application can also prevent issues.

Trapped Air Bubbles

Having discussed the significance of appropriate mixing and temperature regulation, let’s move on to another common culprit for dimples and bumps in epoxy tumblers: trapped air bubbles. These pesky bubbles can form during mixing or application, resulting in an unsightly finish.

Preventing bubbles starts with properly mixing your resin and hardener and bubble troubleshooting techniques. Such as using a heat gun to pop them can also be helpful. Additionally, Tumbler turning techniques while applying epoxy can help release any trapped air pockets.

It should be emphasized that prevention is crucial in avoiding bubbles altogether. Learning resin mixing tips and perfecting your application technique will go a long way in achieving a smooth, professional-looking epoxy tumbler.

Temperature Fluctuations

Now, let’s move on to another common cause of dimples and bumps in epoxy tumblers: temperature fluctuations during curing.

As an epoxy tumbler researcher, it’s essential to consider various heating methods and cooling techniques affecting resin viscosity and application.

Rapid temperature changes can lead to uneven curing, resulting in unsightly bumps and dimples.

It’s also important to consider the tumbler design when working with temperature-sensitive materials, as specific shapes may retain heat differently than others.

Proper temperature control during mixing and curing is critical to achieving a smooth finish on the epoxy cup.

Related Post

You can check How to fix warped resin mold from our team

You can also check How To Get Rid Of Epoxy Smell

How To Prevent Epoxy Tumblers Have Dimples

I’m researching how to prevent dimples and bumps in epoxy tumblers. I’m focusing on two key areas: mixing the resin and hardener correctly and removing air bubbles from the Tumbler.

Mixing the resin and hardener in the exact ratio is essential, as too much or too little of either will result in imperfections.

Additionally, removing any air bubbles that form while the epoxy is curing is essential, as they can cause bumps and dimples on the tumbler surface.

Mixing Resin And Hardener

As an epoxy tumbler researcher, it’s essential to understand the significance of mixing resin and hardener to prevent dimples and bumps. The consistency of the resin and hardener should be considered, as it can affect the final appearance of the Tumbler.

Measuring the correct proportions is essential to ensure the mixture is thick and thick enough. Air bubbles are a common issue that can cause imperfections in the surface. To prevent we should use proper mixing techniques, such as stirring slowly and scraping the sides of the container.

Curing time is also essential in achieving a smooth finish. Following temperature and curing time guidelines for maximum curing without causing unwanted deformations is necessary.

Removing Air Bubbles

Now that we’ve covered the importance of mixing resin and hardener let’s discuss another crucial aspect in preventing dimples and bumps in epoxy tumblers: removing air bubbles.

Air bubbles can cause unsightly imperfections on the surface of your Tumbler, so it’s essential to eliminate them before and during the curing process.

A vacuum chamber or heat gun can help remove bubbles before pouring them into a silicone mold. At the same time, a resin mixer or pressure pot can aid in thorough mixing and reduce the likelihood of air pockets forming.

It’s also essential to apply epoxy evenly and avoid excess pressure, as this can cause more bubbles to form.

Following these guidelines, you can achieve a smooth finish on your epoxy tumbler without any unwanted bumps or dimples.

How To Fix Dimples And Bumps In Epoxy Tumblers

I’m researching the best techniques for fixing dimples and bumps in epoxy tumblers.

Sanding the surface is one option, but using the proper grits and techniques is vital to avoid damaging the Tumbler.

Resin coating can also be effective, but using the right product and following the instructions is essential.

Finally, polishing methods can be used to get a smooth finish. These techniques require different materials and processes, so I’m researching the best approach for each.

Sanding Techniques

Are you tired of seeing those pesky dimples and bumps on your epoxy tumbler? Fear not; as a dedicated epoxy tumbler researcher, I have found that sanding techniques can be an effective solution.

Wet sanding with a fine grit selection, followed by dry sanding with increasingly finer grits, can help to smooth out surface imperfections. After sanding, applying a polishing compound and buffing wheel can further enhance the overall finish of the Tumbler.

It’s important to note that careful attention should be paid to avoid over-sanding and causing damage to the epoxy surface. With these techniques, you can achieve a flawless and smooth surface on your epoxy tumbler.

Related Post

You can check Are epoxy resin grinders safe from our team

Resin Coating

Now that we’ve discussed sanding techniques to fix dimples and bumps on your epoxy tumbler let’s turn our attention to resin coating as an alternative solution.

Resin application can cover imperfections and give your Tumbler a glossy finish, but it requires careful surface preparation to ensure proper adhesion.

The curing process should also be considered, as the resin needs sufficient drying time before handling.

When mixing the resin, follow the recommended mixing ratio for optimal results.

With these considerations in mind, resin coating can be an excellent option for achieving a smooth and flawless finish on your epoxy tumbler.

Polishing Methods

Now that we’ve covered resin coating as an option for fixing dimples and bumps on epoxy tumblers let’s explore polishing methods to achieve a flawless finish.

Hand sanding can remove any roughness left after sanding and prepare the surface for polishing. Buffing techniques, examples of tools that can be used include a rotary tool with a buffing wheel or a handheld buffer. This can subsequently be utilized to enhance the luster of the epoxy.

Resin thickness should also be considered when deciding on polishing methods, as thicker layers may require more sanding and buffing to achieve the desired finish. Curing time is another critical factor, as the epoxy must be fully cured before polishing.

When selecting sandpaper grit for hand sanding or buffing pads for rotary tools, it’s best to start with a lower determination and work up gradually to avoid damaging the epoxy surface.

You can achieve a professional-looking result by incorporating these polishing methods into your tumbler-making process.

Conclusion

As an epoxy resins art researcher, it is essential to understand the root cause of dents and why does my epoxy tumbler have dimples.

A critical factor that contributes to this visual effect is inadequate material selection. Choosing quality resin and hardener can go a long way in preventing these imperfections.

Additionally, taking care of the curing process, such as ensuring proper temperature and humidity levels, can help eliminate dimples.

Another essential factor is surface preparation – thoroughly cleaning and sanding the Tumbler before applying the epoxy can improve adhesion and prevent bumps from forming.

These steps can help us accomplish

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Наиболее актуальные новости мировых подиумов.

Все мероприятия лучших подуимов.

Модные дома, торговые марки, haute couture.

Самое приятное место для трендовых хайпбистов.

https://km-moda.ru/style/525-parajumpers-istoriya-stil-i-assortiment/

Точно трендовые события моды.

Важные события самых влиятельных подуимов.

Модные дома, торговые марки, высокая мода.

Новое место для трендовых хайпбистов.

https://luxe-moda.ru/chic/356-rick-owens-buntar-v-chernyh-tonah/

Абсолютно свежие события мировых подиумов.

Важные эвенты всемирных подуимов.

Модные дома, лейблы, haute couture.

Самое приятное место для стильныех хайпбистов.

https://modastars.ru/

Абсолютно важные события подиума.

Актуальные новости известнейших подуимов.

Модные дома, бренды, высокая мода.

Лучшее место для трендовых людей.

https://donnafashion.ru/

Real great info can be found on blog.Raise your business

Полностью актуальные новости модного мира.

Актуальные мероприятия лучших подуимов.

Модные дома, торговые марки, высокая мода.

Приятное место для стильныех хайпбистов.

https://mvmedia.ru/novosti/282-vybiraem-puhovik-herno-podrobnyy-gayd/

Несомненно стильные новинки модного мира.

Все события всемирных подуимов.

Модные дома, торговые марки, высокая мода.

Самое лучшее место для трендовых хайпбистов.

https://donnafashion.ru/

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Абсолютно стильные новости моды.

Важные новости мировых подуимов.

Модные дома, торговые марки, гедонизм.

Приятное место для стильныех хайпбистов.

https://lecoupon.ru/